details

The main characteristics of the motion control system of tin welding machine are as follows:

Large capacity storage. 200 storage files, single file support up to 60,000 teaching points;

Comprehensive USB support. Support teaching box and U disk to copy files each other, support remote system upgrade;

_Three-dimensional array function. Easily deal with die deviation;

Group function. Quick replication, deletion, correction, array, migration of multiple points;

_Program file connection function. Complex multi-layer irregular array and non-array pattern interleaving processing can be realized.

_Subprogram call function. Subprograms can be called unconditionally, conditionally, sequentially and in parallel.

_Multiple and flexible process parameters setting;

_The feeding quantity can be controlled by a single point or figure.

Faster speed. It has the function of position foresight and speed foresight.

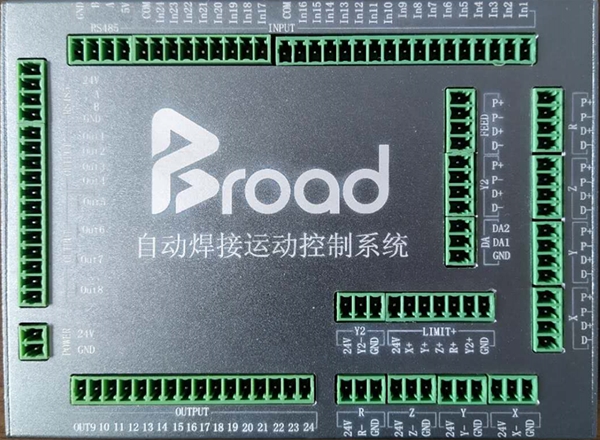

More choices. Including double Y axis, rotation axis and other four axes expansion;

There are 24 general input channels and 24 general output channels.

With relay-type output port, no additional relay is needed when photoelectric isolation or non-polar signal is needed.

It has special alarm input interface and special function fast interface.

_The input port can choose NPN sensor or PNP sensor.

Provide a variety of processing modes, such as single-step operation, simulation operation, whole processing and automatic cyclic processing.

Programming elements such as pause, jump and subroutine greatly improve the flexibility of programming.

_has the function of breakpoint renewal.

Large capacity storage. 200 storage files, single file support up to 60,000 teaching points;

Comprehensive USB support. Support teaching box and U disk to copy files each other, support remote system upgrade;

_Three-dimensional array function. Easily deal with die deviation;

Group function. Quick replication, deletion, correction, array, migration of multiple points;

_Program file connection function. Complex multi-layer irregular array and non-array pattern interleaving processing can be realized.

_Subprogram call function. Subprograms can be called unconditionally, conditionally, sequentially and in parallel.

_Multiple and flexible process parameters setting;

_The feeding quantity can be controlled by a single point or figure.

Faster speed. It has the function of position foresight and speed foresight.

More choices. Including double Y axis, rotation axis and other four axes expansion;

There are 24 general input channels and 24 general output channels.

With relay-type output port, no additional relay is needed when photoelectric isolation or non-polar signal is needed.

It has special alarm input interface and special function fast interface.

_The input port can choose NPN sensor or PNP sensor.

Provide a variety of processing modes, such as single-step operation, simulation operation, whole processing and automatic cyclic processing.

Programming elements such as pause, jump and subroutine greatly improve the flexibility of programming.

_has the function of breakpoint renewal.

- Previous:200 series soldering iron

- Next:Automatic production line

You may also be interested in this product